In the race to scale up a global supply chain for electric vehicle batteries, mining justice advocates have sought to ensure that the ongoing clean technology minerals boom does not exacerbate longstanding negative impacts from the global mining industry. Chief among these are corruption risks.

To provide guidance to electric vehicle purchasers (particularly fleets), advocates, and leaders in “downstream” markets about how to support anti-corruption measures in the battery supply chain, Berkeley Law’s Center for Law, Energy and the Environment (CLEE) partnered with the Natural Resource Governance Institute to issue a new policy brief: Corruption Risks in the EV Battery Supply Chain: What Advocates, Automakers and Fleet Purchasers Can Do.

The brief presents a set of actions for “downstream” markets, such as in the United State and European Union. Among the steps that the report recommends these actors take:

- Battery manufacturers, automakers, and fleet purchasers could integrate checks on corruption risks into responsible sourcing and due diligence systems. Risks from supply chain relationships may directly affect company operations, and companies can leverage their influence to promote better practices and policies. When necessary, they should be willing to disengage or suspend engagement with suppliers.

- Manufacturers, automakers and purchasers could also encourage project-level contract, payment, commodity trading, and beneficial ownership transparency and robust ethics and compliance policies from suppliers. Companies could look for comprehensive project or sale-level disclosure of contracts and licenses, payments to governments, and verified beneficial ownership information, internal oversight and independence of ethics and compliance procedures, robust disciplinary and remediation procedures.

- Electrification and sustainable mining advocates in North America and Europe could emphasize the importance of governance and anti-corruption measures in their advocacy. Specifically, advocates can better incorporate anticorruption into benchmarks or reports that assess companies’ sustainability provisions and/or responsible sourcing.

- Advocates could push for governments to incorporate strong anticorruption provisions into sustainability criteria for mining projects, in policies and legislation addressing responsible sourcing or due diligence, and in partnerships or trade deals with mineral-producing countries.

Ultimately, corruption is not a victimless crime. It undermines trust in government and deprives the public of needed revenues from mining projects. It can also jeopardize supply chain affordability and reliability as the world makes this critical transition to a cleaner transportation system. With the steps outlined in Corruption Risks in the EV Battery Supply Chain: What Advocates, Automakers and Fleet Purchasers Can Do, advocates, purchasers and downstream market leaders have an opportunity to ensure that the electric vehicle mining boom doesn’t replicate past and ongoing harms from the global mining sector.

We need electric vehicles to fight climate change, and that means a lot of mining for minerals like lithium and graphite for the batteries. It’s better if that mining happens in the US rather than overseas, where worker and environmental protections may be weaker. But we still need to improve mining processes here.

My new op-ed in The Hill has recommendations on how to do so, following the release of a new federal interagency report on mining. The report calls for permitting agencies to conduct better upfront planning to ensure new mining activity is not sited in sensitive areas that would likely produce conflict, litigation and delay. To do this, I argue:

Specifically, the country can take its cue from California, where a public-private partnership among state government, academic institutions and nonprofits pioneered a stakeholder-led process to map lands for large-scale solar development in key regions in the state. That process resulted in the identification of hundreds of thousands of “least conflict” acres, which participants as diverse as Tribes, ranchers, endangered species advocates and developers agreed would be feasible to develop without harming communities or important resources. This approach is now being replicated in other states.

If we can pull this process off in this country, the result would be fewer conflicts, a more sustainable supply chain for EV batteries, and economic and environmental wins for the communities surrounding mines, including many tribal and rural communities. And maybe it could provide a model for other jurisdictions to follow suit, as the world undergoes a dramatic and badly needed transformation in its vehicle fleet to EVs.

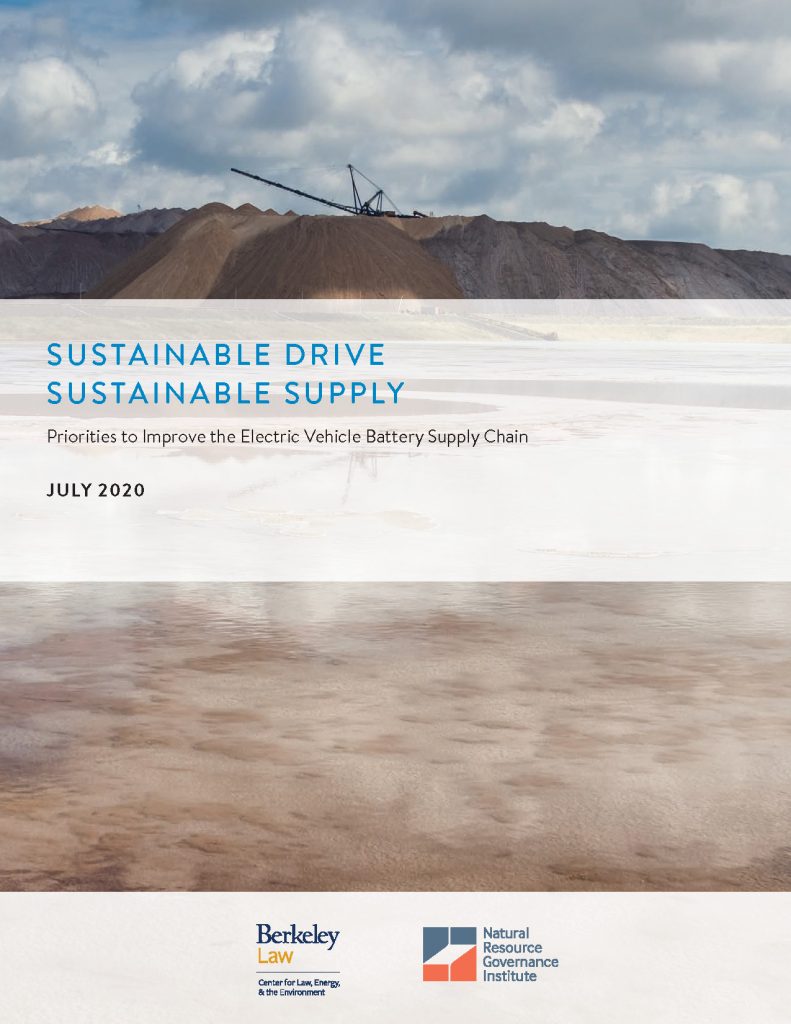

CLEE and the Natural Resource Governance Institute (NRGI) are pleased to release today the new report “Sustainable Drive, Sustainable Supply: Priorities to Improve the Electric Vehicle Battery Supply Chain.” The report identifies key challenges and solutions to ensure battery supply chain sustainability through a multi-stakeholder approach, based on our outreach to experts in the field.

The global transition from fossil fuel-powered vehicles to battery electric vehicles (EVs) will require the production of hundreds of millions of batteries. This massive deployment frequently raises questions from the general public and critics alike about the sustainability of the battery supply chain, from mining impacts to vehicle carbon emissions.

To address these questions, CLEE and NRGI are conducting a stakeholder-led research initiative focused on identifying strategies to improve sustainability and governance across the EV battery supply chain. CLEE and NRGI convened leaders from across the mining, battery manufacturing, automaker, and governance observer/advocate sectors, to develop policy and industry responses to human rights, governance, environmental, and other risks facing the supply chain.

“Sustainable Drive, Sustainable Supply” identifies the following key challenges to ensuring battery supply chain sustainability:

- Lack of coordinated action, accountability, and access to information across the supply chain hinder sustainability efforts

- Inadequate coordination and data sharing across multiple supply chain standards limit adherence

- Regulatory and logistical barriers inhibit battery life extension, reuse, and recycling

The report recommends the following priority responses that industry, government and nonprofit leaders could take to address these challenges:

- Industry leaders could strengthen mechanisms to improve data transparency and promote neutral and reliable information-sharing to level the playing field between actors across the supply chain and between governments and companies

- Industry leaders and third-party observers could ensure greater application of supply chain sustainability best practices by defining and categorizing existing standards and initiatives to develop essential criteria, facilitate comparison and equivalency, and streamline adherence for each segment of the supply chain

- Governments and industry leaders could create new incentives for supply chain actors to participate in and adhere to existing standards and initiatives, which may include sustainability labeling and certification initiatives

- Industry leaders could design batteries proactively for disassembly (enabling recycling and reuse), and industry leaders and governments could collaborate to build regional infrastructure for battery recycling and transportation and create regulatory certainty for recycling

We hope the responses to the supply chain challenges outlined in this report will provide guidance on the initial actions stakeholders can take to make this broader vision of implementation a reality, ensuring a more robust future for communities around the globe as well as for all-important electric vehicle adoption to meet climate change goals.

To learn more about this issue and the new report, join our 9am PT / Noon ET webinar today, featuring:

- Patrick Heller, Senior Visiting Fellow, Center for Law, Energy & the Environment (CLEE) & Advisor, Natural Resource Governance Institute (NRGI)

- Michael Maten, Automotive Public Policy, Electrification, Portfolio Planning and Strategy, General Motors

- Daniel Mulé, Senior Policy Advisor for Tax and Extractive Industries, Oxfam

- Payal Sampat, Mining Program Director, Earthworks

You can register for the webinar; read our recent FAQ on EV batteries for more information on current supply chain impacts on human rights, climate change and the local environments; and download the new report “Sustainable Drive, Sustainable Supply: Priorities to Improve the Electric Vehicle Battery Supply Chain.”