The Reno Gazette-Journal checks in for an update on the battery megafactory, and the results are mixed to date:

The Tesla-Panasonic battery gigafactory is falling far short of the economic impact projections on jobs and capital investment used to persuade lawmakers to approve a record-breaking tax incentive package for the project, according to an analysis by the Reno Gazette-Journal.

According to the review of available public documents, the project has generated just a fraction of the jobs, payroll and capital investment projected for the first year in a study commissioned by the Governor’s Office of Economic Development during the 2014 special session.

The numbers also have not kept up with the more refined projections used by Tesla in its application for incentives that will allow the company to operate tax free for a decade and with substantially reduced taxes for a second decade.

Nevada leaders don’t sound worried because the tax benefits go away if certain benchmarks aren’t met. And the factory is already starting to produce home batteries for stationary energy storage.

At this point, it’s probably not a cause for concern, although it may be an indication that construction isn’t where Tesla hoped to be at this point.

Long term, the real value in the Gigafactory for the Reno area is not in construction jobs, but in the higher-paid engineering and other high-skilled jobs that will be located on-site, plus all the supply and service industries that will spring up as a result nearby.

At least Nevada leaders hope that’s the case, given the tax breaks they gave Tesla to lure them there in the first place.

Analysts are predicting a bright future for battery costs, thanks in large part to Tesla’s under-construction Gigafactory in Nevada:

Tesla’s grid battery, the Powerwall, is currently priced at about $250/kWh, but CTO JB Strabuel said at a recent utility conference that he expects that price to drop to about $100/kWh by the end of the decade as the company ramps up production.

That ambitious estimate is now being approached by other analyst predictions.

“Our detailed battery component cost analysis details a path to 50%+ reduction in battery pack cost to $125/kWh by 2020,” [Jefferies analyst Dan] Dolov said, according to StreetInsider. Jefferies expects the battery cells themselves to reach about $88/kWh by the end of the decade, and the battery packs to reach about $38/kWh.

A 50% reduction by 2020 would be monumental for the electric vehicle industry. Imagine double the range of current all-battery vehicles at the same price tag ($30K or so for the LEAF, for example). Imagine a high-end Tesla at $20-30K off the current price.

It’s worth keeping in mind that these predictions are only about 2020. By 2030, when we need all new vehicles to be battery-electric to meet our climate goals, prices should come down even more, while public charging infrastructure will only improve.

And as I’ve said before, it’s not just about transportation. These batteries will be needed in bulk to store surplus solar and wind power to decarbonize the grid.

Basically, if you care about climate change, these kind of price forecasts are the most important pieces of news in the field.

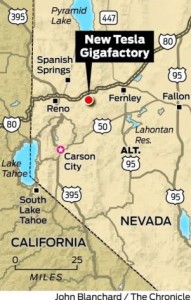

Some California environmentalists may be celebrating now that Tesla has apparently decided to build its $5 billion “gigafactory” in Nevada instead of California. Lawmakers here had toyed with the idea of weakening the state’s signature environmental law, the California Environmental Quality Act (CEQA), to help expedite review on the factory and therefore encourage Tesla to locate in-state, possibly in Stockton. But those plans fell through last week.

But Tesla’s decision could be an overall setback for the environment, compared to building a factory in California. To be sure, the idea of a gigafactory is a huge win for the environment overall. The cheaper batteries will encourage more adoption of electric vehicles and also help clean our grid by enabling inexpensive storage of surplus wind and solar energy.

So why is Nevada so bad, compared to California? First, the siting of the gigafactory will likely launch a major manufacturing program, with an attendant industry likely to spring up around it, in a state with much weaker regulation than California. Nevada ranked 20th among US states in a George Mason University survey of the most lax regulatory states when it comes to land use decision-making, with California ranked 49th. And a recent comprehensive survey of business owners gave Nevada an “A” on the impact of environmental regulations on business, which is not a good sign for environmental protection. California of course received an “F.” So the factory itself, as well as any future co-located suppliers, will operate with less future oversight for environmental health and safety protection.

In addition, the thousands of workers who will be employed there will likely end up in new subdivisions that sprawl over the high desert countryside, if Reno’s past growth is any indication. And they will likely commute to work by car, a lifestyle that Californians are rapidly abandoning. California meanwhile is engaging in regional transportation plans that will offer alternative, more environmentally friendly housing and transportation for workers, and its environmental laws are now encouraging growth closer to jobs and services.

Finally, from a shipping perspective, the factory in Nevada will have to transport the batteries by train to the major population centers in San Francisco and Los Angeles, which are the leading markets to buy electric vehicles. Locating the factory in Stockton would have reduced this shipping distance significantly, along with its associated environmental impacts, while placing the factory only a negligibly farther distance from the East Coast markets.

Tesla CEO Elon Musk has said that he plans to build more such factories. And as I say, the gigafactory is an overall environmental win. Yet while California’s economy would certainly benefit from locating it in-state, the environment would as well, compared to the site announced today.

Western states like California are falling all over themselves to secure Tesla’s proposed “gigafactory” to mass-produce lithium ion batteries. This cheap energy storage will be a game changer for making electric vehicles affordable and decarbonizing our electricity supply by balancing intermittent renewables from the sun and wind. But for state leaders, the factory means great middle class jobs in an expanding clean-tech industry.

Texas seemed to have the lead, but California is pulling out all the stops, including waiving key environmental laws like the California Environmental Quality Act (CEQA). Now it appears that if the factory happens in California, it may be in Stockton, according to the Los Angeles Times. Stockton is just an hour outside of the Bay Area in the Central Valley, with many people commuting into the Bay Area there from cheaper middle-class sprawl developments. Plus it has access to waterways, freeways, and the Tesla vehicle factory.

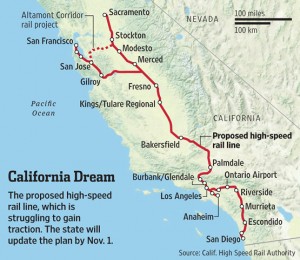

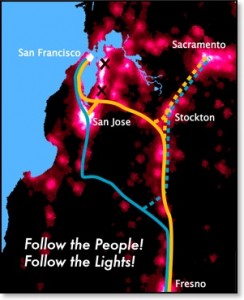

But if the factory does happen in Stockton, it should also have access to high speed rail. A decision to locate the gigafactory there should prompt the California High Speed Rail Authority to reconsider its proposed route to the Bay Area from the south via Pacheco Pass and pristine, rural San Benito County. That route is not my favorite — it cuts off major population centers, including Stockton and Modesto, and puts a beautiful, undeveloped part of the state at risk of rail-induced sprawl. It does serve San Jose more directly, but the city could still be served by a spur from an Altamont route. Here’s the current proposed route:

And here’s the alternative Altamont Pass route that would provide access to Stockton and the possible factory (source is the advocacy group Transdef):

And here’s the alternative Altamont Pass route that would provide access to Stockton and the possible factory (source is the advocacy group Transdef):

The Authority just won a CEQA case on appeal upholding environmental review on the Pacheco alignment. But maybe the prospect of the gigafactory, combined with the other benefits of routing the system along Altamont, will prompt long-overdue reconsideration.

The Authority just won a CEQA case on appeal upholding environmental review on the Pacheco alignment. But maybe the prospect of the gigafactory, combined with the other benefits of routing the system along Altamont, will prompt long-overdue reconsideration.